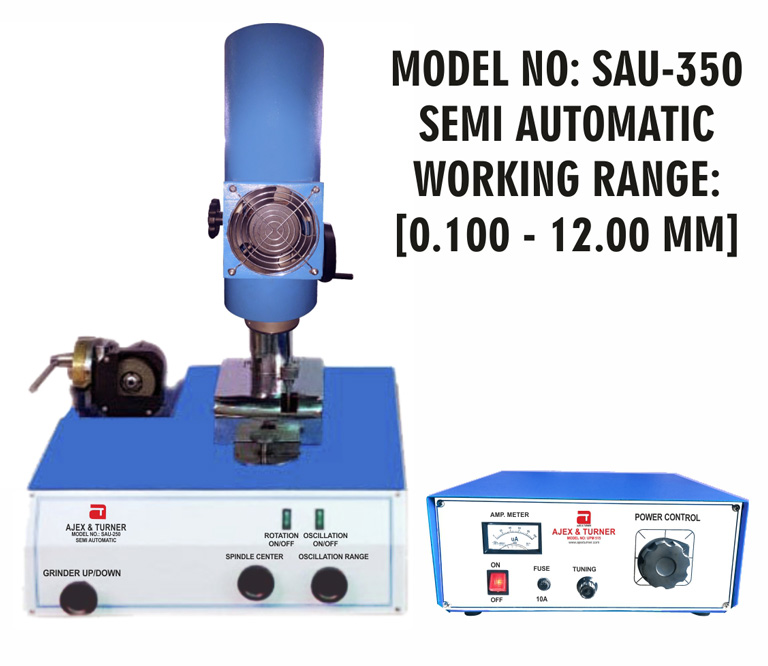

The machine in designed & developed for resizing & re-polishing of PCD mix ranges 0.5-12.00mm, The machine mainly consist of Ultrasonic Generator, Rotating Ultrasonic Head, Oscillating die table & built in Needle Grinder. Needle fixing is by soldring for optimum transfer of Ultrasonic power. The Die table oscillation movement is motorized The die pressure is magnetic. The speciality of machine is that accurate die angle can be produced repeatedly. The Frequency & the amplitude of the Ultrasonic waves can be varied.

| Size Range | Shaping Time (in minutes) |

Polishing Time (in minutes) |

|---|---|---|

| 0.2-0.50 | 7-10 | 30-40 |

| 0.51-1.00 | 15-20 | 40-50 |

| 1.01-2.00 | 20-25 | 45-50 |

| 2.01-5.00 | 20-40 | 50-90 |

*Polishing & recutting time may vary as per the dimension of pcd nib size

Standard Accessories : Supplied with Machine SAU 350 | Soldering steel needles for horn : ø 2, 3, 4, 6, 8 & 10 pcs each I one bottle of oil Spanner: (18-19) - 1 nos (16-17) 1no | Water can 1 no | adhesive one bottle | Round Belt : ø 4 & 6 X 500 mm - 1 no each Fuse : 5 Amps & 1OAmps - 10 nos | 1 no Grinding Wheel | Horn : ø 8, 10 & 12 mm each 5 nos | soldering paste - 100 grams | Diamond Powder 0 - 0.25 O - 0.50 | 1 - 3 | 2 - 4 | 4 - 8 | 20 - 30 | 30 - 40 25 carat each.

SUCCESSFUL SHOW AT WIRE SOUTHEAST ASIA HELD IN BANGKOK

SUCCESSFUL SHOW AT WIRE SOUTHEAST ASIA HELD IN Mumbai Exhibitions 2018